It has a nice view of the distillery:

and the warehouse.

There, we found a small museum that provided an introduction to bourbon and the distillery, as well as some free peach iced tea that Mike really liked.

What started our quick tour of bourbon distilleries was a visit to the Woodford Reserve distillery, which is quite close to the bed and breakfast.

To schedule for a tour, see the gift shop, etc. we went to their tourist welcoming house.

It has a nice view of the distillery:

and the warehouse.

There, we found a small museum that provided an introduction to bourbon and the distillery, as well as some free

peach iced tea that Mike really liked.

From the Woodford Reserve web site:A side note is that Bourbon does not have to come from Kentucky - it can be made anywhere in the United States....but mostly only the distilleries in Kentucky adhere to the "nothing else added" rule, whereas many other whiskeys will add other flavors during their processing.

"What Is Bourbon?In 1964, during Bourbon-fancier Lyndon Johnson's administration, the U.S. Congress passed a resolution declaring Bourbon "a distinct product of the United States." No whiskey can call itself Bourbon unless it meets the following criteria:

- Must be made in the United States

- Distilled at less than 160 proof from fermented grain mash

- The grain recipe must be at least 51% corn

- The product must be stored in new, charred, white oak barrels at no more than 125 proof

- Nothing can be added to the final product except pure water

Most Bourbons are aged for at least four years. At Woodford Reserve we pay no attention to the calendar. Because we have very exacting standards with regards to color, aroma and taste, it is up to the palate of our master distiller, Chris Morris, to tell us when a barrel is ready. Every barrel matures at a different rate.

How Bourbon Got Its Name

The name Bourbon comes from France. During the Revolutionary War, the American patriots received help from the French. The ruling family on the throne of France at that time was the Bourbon family. To honor the French for helping us win the war, the area between Lexington and Maysville, Kentucky, was named Bourbon County. At that time, Maysville, located on the Ohio River, was a major shipping port and was called Limestone. In the 1800s the prized corn-based beverage, shipped out of Limestone, down the Ohio and Mississippi Rivers to New Orleans, then around the world, came to be known as "whiskey from Bourbon County."

Eventually, its name was shortened to Bourbon. To further recognize the French influence on the area, the county seat of Bourbon County is Paris, and not far from Lexington is the city of Versailles (pronounced "Ver-sales") in Woodford County - the home of our distillery."

Our tour started with a movie, where we learned that the distillery had been named a national landmark:

From the Woodford Reserve web site:

"In May, 2000, U.S. Secretary of the Interior Bruce Babbitt announced the designation of the Woodford Reserve Distillery in Woodford County, Kentucky, as a National Historic Landmark. Woodford Reserve was one of 15 properties in 10 states recommended to the Secretary for this designation by the National Park System Advisory Board for their national significance in American history and culture. "

"In recommending Woodford Reserve as a National Historic Landmark, the advisory board said: "As the birthplace of Bourbon in the 1830's, this site illustrates, like no other property, the history of Bourbon distillation in Kentucky. With its intact rural setting, Woodford Reserve presents the evolution of the craft from the traditional pot still distilling of farmers during the 19th century to the mature and highly specialized industry of the post-Repeal era. Of all Kentucky distilleries, Woodford Reserve is closely associated with the development of Bourbon as a distinctive Kentucky alcoholic beverage and the one that became the leading export of the United States." "

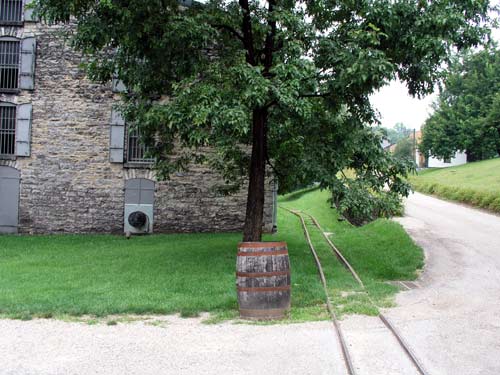

We then took a small bus down the hill to the distillery, where we could see more of the distillery complex:

the rails used to roll barrels to the warehouse:

and the welcome house, as seen from the bottom of the hill.

Here's Mike with the tour group, as we get ready to enter the first building.

We got a description of the grains used to make Bourbon and we could see the bottom of the vats used for fermenting.

Here's Mike upstairs, where we could see the top of the vats.

From the Woodford Reserve web site:

"The process of making Bourbon begins with the selection of the finest grains possible; for Woodford Reserve we use corn, rye and malted barley. The corn, which serves as a source of starch and brings sweetness to the taste, and rye, which also provides starch and adds spiciness, are milled, then cooked with limestone water. A portion of the prior batch is used to "sour" the next and is called "set back." This provides consistency to the product. "

"During the "cook" the starches in the corn and rye are released and their conversion into fermentable sugar is caused by enzymes in the malted barley. "

"The mash is then pumped to the cypress fermentation vats where we introduce our proprietary strain of yeast that converts the fermentable sugar into alcohol called "distiller's beer." The yeast imparts unique flavor characteristics to the spirit. We allow the mash to ferment up to seven days, choosing not to rush the process. "

"As you enter the Distillery Building to start the tour, you are engulfed by the aroma of our "sour mash" coming from the 14 foot high cypress fermentation tanks. "

"Following the Civil War, distillers in Kentucky favored using cypress fermenters because they were very resilient to water and held up well over time. They also did not give unwanted character to the product, as might cedar or oak. Our four fermenters, in addition to being 14 feet high, are 10 feet across, and have a capacity of 7,500 gallons, tiny when compared to other Kentucky distillers. In order to be faithful to our distilling heritage, this is the only Bourbon distillery that ferments all its mash in cypress."

"As stated previously, during fermentation, alcohol is produced when the yeast and the fermentable sugars in the grains interact. During the process bubbles rise to the surface. These bubbles are carbon dioxide, a natural by-product of fermentation. When fermentation is complete, the result is "distiller's beer," which is approximately 18 proof or 9% alcohol. At that point, the "beer" is pumped to the Still Room to begin the distillation phase. "

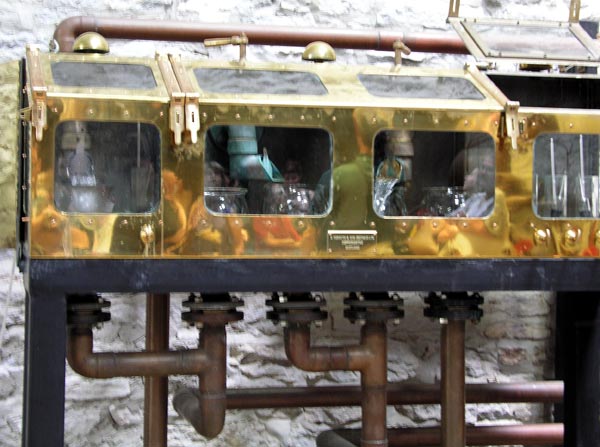

From there, we walked into the distillation room, with 3 very large stills. The process starts with the still furthest away and works

through the middle still, and finally the one in the foreground.

and sample output from the stills that the brewers can use for quality assurance.

From the Woodford Reserve web site:

"The same old-country artisans who directed construction of these nearly 200 year-old structures crafted their whiskey in copper pot stills. At The Woodford Reserve Distillery, we're very proud of our heritage and want to continue the traditions started here by our ancestors, so we're following their example. In fact, this is the only distillery in Kentucky today making Bourbon using copper pot stills, the traditional method of distillation. "

"Copper is an excellent metal for use in distilling. It's sanitary, an excellent heat conductor, and also reacts favorably with alcohol vapors, imparting unique qualities that make for a superior whiskey. In Scotland and Ireland, pot stills are still used today for distilling Scotch and Irish whiskey. A. Forsythe & Son, one of the world's foremost coppersmiths, made our stills at their fine facilities in Rothes, Scotland expressly for us."

"The first "charge" (2500 gallons, or one-third of the fermenter's capacity) is pumped from the fermenter into still #1, called the "beer still." During distillation, the alcohol is separated from the water. "

"Steam is injected into the pot still and the alcohol vaporizes up the gooseneck, exposing the vapor to the copper inner surface. The vapor cools as it passes through a condenser that converts the vapor into a liquid called "low wine." The low wine is 40 proof or 20% alcohol. "

"During the second distillation, we pump the low wine into the "high wine" still. As we heat this liquid the alcohol vaporizes a second time, goes through the condensation process again, and emerges as "high wine" at about 100 to 110 proof (50 - 55% alcohol). With each distillation, more impurities and water are removed from the liquid. "

"Finally, we pump the "high wine" into the "spirit still," where it's distilled a third and final time, resulting in a 158 proof product. At this point, we are through distilling and our clear "new spirit" is ready to go into our barrels."

The last stop in this building was an area dedicated to barrels and the making of barrels. Samepl empty barrels were on display:

From the Woodford Reserve web site:and don't worry....even though all barrels used for making Bourbon are brand new, after they have been emptied, they are sold to other whiskey and scotch distilleries. Having a few year's worth of Bourbon soak into these barrels means that other liquors aged in those barrels will pickup a hint of the bourbon flavor.

"At The Woodford Reserve Distillery, we buy our barrels from Bluegrass Cooperage, in Louisville, Kentucky. The barrels play a critical role in the maturation of Bourbon. We hand select barrels made expressly for us at Bluegrass. Since we fill only 70 barrels a week, we must be very discriminating about their quality."

"The barrels are made of white oak. This wood became the standard for all Bourbon distillers because of its availability in Kentucky, its strength, its sugar content, and other excellent properties for maturing whiskey."

"The "Cooper" - or barrel-maker - is a true craftsman. When white oak comes to the cooperage, it's very rough and must be planed smooth. Then it's cut into 28" to 31" staves, sanded and tapered. It requires skill and experience to make the staves fit snugly within this iron circle because the barrel must hold together without the benefit of nails or glue. At this point, the staves in the raised barrel are permanently bent into shape using steam. "

"Next the barrel is toasted for approximately 22 minutes using radiant heat to caramelize the sugars in the wood. These caramelized sugars produce the sweet vanilla taste and caramel aroma one tastes and smells in Bourbon. After toasting, the barrel is then set on fire for about 20 seconds. This forms a layer of char about 1/8 of an inch in thickness on the inside surface of the barrel. The char layer contributes to the rich amber color of Bourbon."

"Our barrelheads are formed by a separate process and installed by hand. Woodford Reserve's barrelheads are specially toasted and charred to increase the effect of maturation. At this point the barrel is ready to receive our product to begin the aging process."

We walked outside to get warehouse. No, they don't use the water from this stream...

Unlike some distilleries, Woodford Reserve does not rotate their barrels. What surprised us most was the cat wandering

around the rafters. He is a permanent resident at the distillery, and I caught up with him outside the warehouse.

From the Woodford Reserve web site:

"We add demineralized water to our 158 proof (79%) product to bring the product down to "entry proof," which is 110 proof (55%). To move the filled barrels from the Distillery Building to our warehouses, we use a barrel run, a small-gauge set of rails. The barrel run at Woodford Reserve is 500 feet long and allows one person, with the help of gravity, to easily move a barrel weighing 500 pounds from the distillery building to the warehouses to begin the maturation process."

"This is Warehouse C, the oldest surviving stone aging house in the U.S., built in the late 1880's. Warehouses are where we mature our whiskey and where the "magic" of turning whiskey into Bourbon takes place. The whiskey in the barrels goes into the warehouses clear and leaves some years later a rich amber liquid called Bourbon. How does this happen? During our hot Kentucky summers the whiskey in the barrel expands, forcing its way through the toasted and charred layers of the barrel and into the wood where it stays until the cold winters cause the whiskey to contract. When this happens, the liquid is pulled back through the layers a second time. This passage in and out of the wood is referred to as a "cycle." With each cycle the product in the barrel picks up more color, aroma and taste. Normally Mother Nature gives you 4-5 cycles a year."

"To ensure the quality of the product throughout maturation, we sample every barrel. Because we mingle in small batches prior to each bottling, we must be confident every barrel meets our exacting standards with regard to color, aroma and taste."

"As the whiskey moves in and out of the wood, with each cycle the product picks up more color, aroma and taste. Over time the clear liquid is transformed into a glorious amber elixir, Woodford Reserve. "

"At Woodford Reserve we pay no attention to the calendar when it comes to determining when each barrel is ready to be bottled. That is left up to the palate of Chris Morris, our Master Distiller, and Dave Scheurich, our Distillery Manager. Only when they say the barrel is ready does the product inside get bottled."

The final part of tour brought us through the building with the bottling line.