By far, the

Jim Beam distillery was the largest we visited. There was no official

tour, so we started in the "American Outpost" building, where we saw a short film about the company's history and bought

some souvenirs.

From there, we visited the main house, where we found a model of the distillery and were treated to samples of

some of their higher end bourbons.

Down the hill from the house was a miniature museum of the old barrel making facility.

The sign in the "Copper shop" shows the steps for making a barrel are:

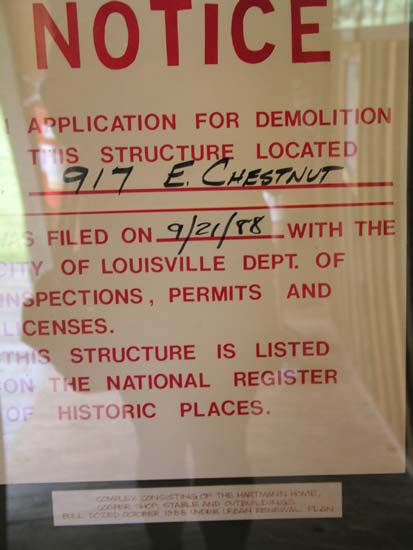

"NOTICE: An application for demolition of this structure located at 917 E. Chestnut was filed on 9/21/88 with the City of Louisville Dept of Inspections, Permits, and Licenses. This structure is listed on the National Register of Historic Places."The sign below it reads

"Complex consisting of the Hartmann home, Cooper shop, stable and outbuildings bull dozed October 1988 under Urban Renewal Plan".

Our final stop was the warehouse.

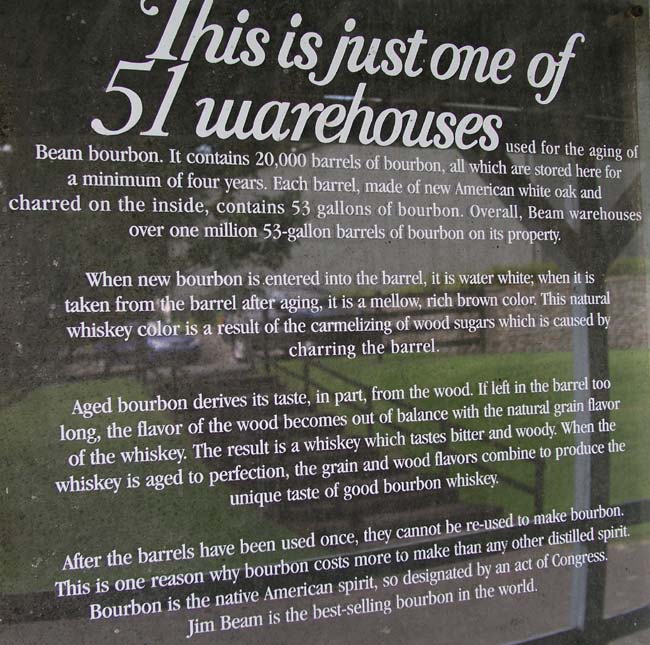

The sign reads:

"This is just one of 51 warehouses used for the aging of Beam bourbon. It contains 20,000 barrels of bourbon, all of which are stored here for a minimum of four years. Each barrel, made of new American white oaks and charred on the inside, contains 53 gallons of bourbon. Overall, Beam warehouses over one million 53-gallon barrels of bourbon on its property."

We took a few more pictures of the factory on our way out.