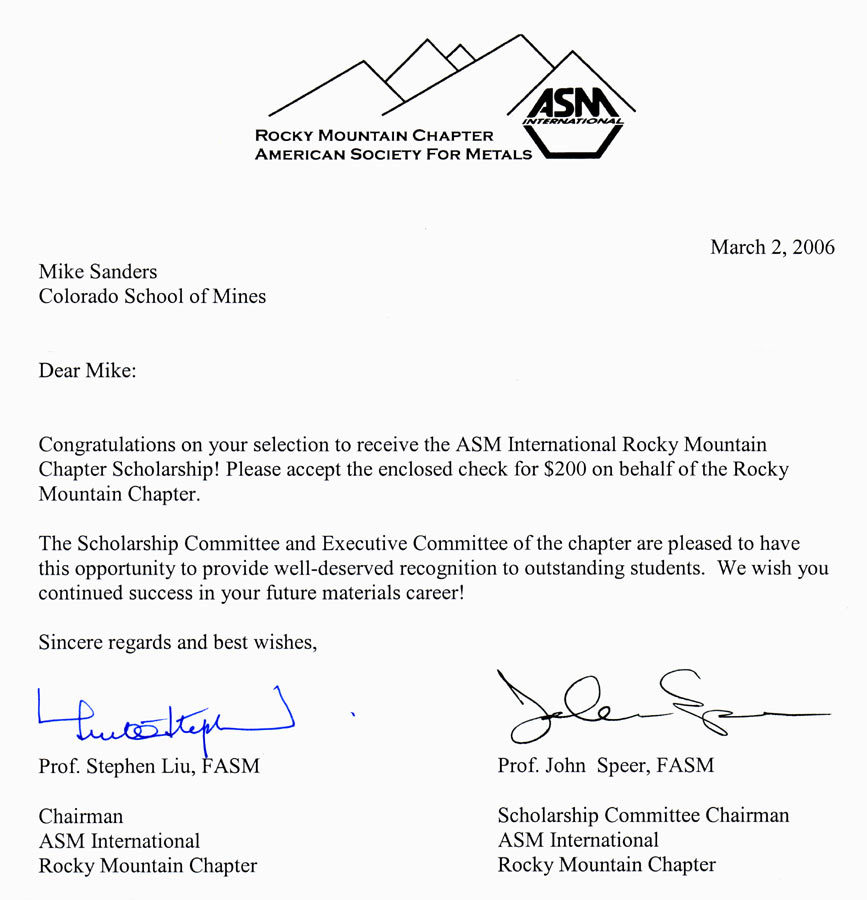

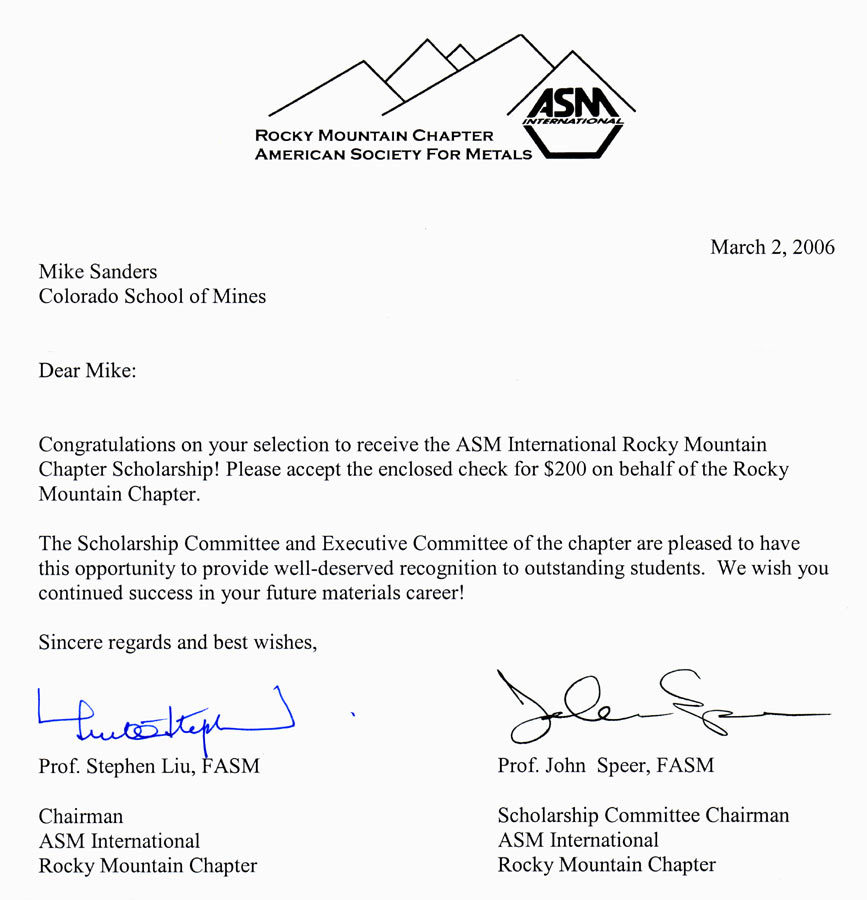

We attended the Charles S. Barrett (a pioneer in x-ray crystallography) Silver Medal award presentation dinner by the local

chapter of the American Society for Metals. The dinner was

held in one of the Mines Student Center's conference rooms, and was attended by professional members of the chapter,

professors, students, an Australian member of the ASM board of trustees, and one local high school science teach who brought two of her students. The teacher was recognized,

several students (including Mike) were given scholarship awards, and one professional from

LiquidMetal Technologies was

awarded the Charles Barrett award. The recipient presented information on his work in BMG (Bulk Material Glasses) -

an amorphous metal technology used to make

parts with much more precision than what can be manufactured through traditional metal working

or plastics. The process uses specially formulated compounds that can be forced to avoid a crystallized material state.

On their crystallography analysis, this means that the material properties show up as smoothly varying lines instead of

distinct sharp diffraction lines for each of the materials in a crystal structure. Combining their small scale and precision

manufacturing abilities with the alloy's superior strength, the company has had contracts to manufacture a wide

range of parts - hinges for flip cell phones, cell phone covers, the casing for the SanDisk USB Flash Drives (like the one

Mike has), and defense projects like the

Kinetic Energy Penetrator (KEP) rod. The KEP takes advantage of the alloy's "self sharpening" property - meaning that

as the rod penetrates something, the material constantly shears to constantly create a new sharp surface.

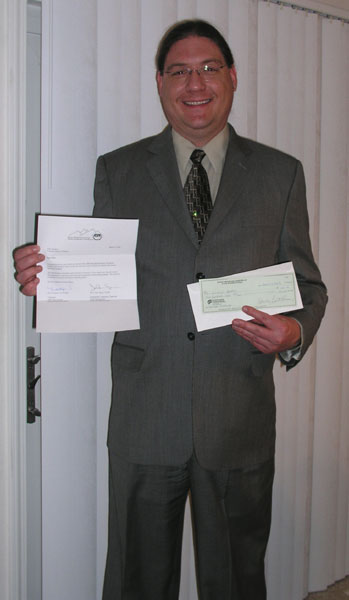

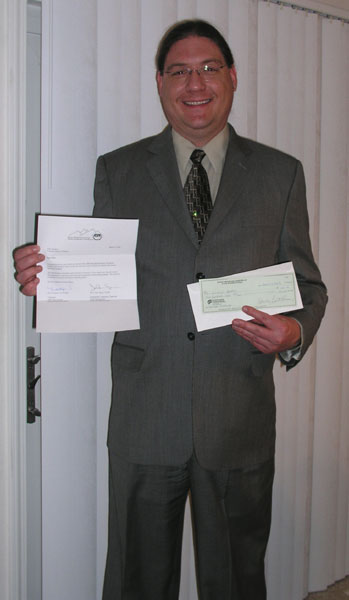

Mike received a scholarship from the Rocky Mountain Chapter of ASM, as seen below: